Exploring Hybrid Powertrain Technologies

Hybrid powertrain technology represents a significant evolution in automotive engineering, combining traditional internal combustion engines with electric propulsion systems. This approach aims to enhance fuel efficiency and reduce emissions, addressing growing environmental concerns and consumer demand for more sustainable transportation options. Understanding the various configurations and operational principles of these systems is crucial for appreciating their role in modern mobility and their potential impact on the future of personal vehicles.

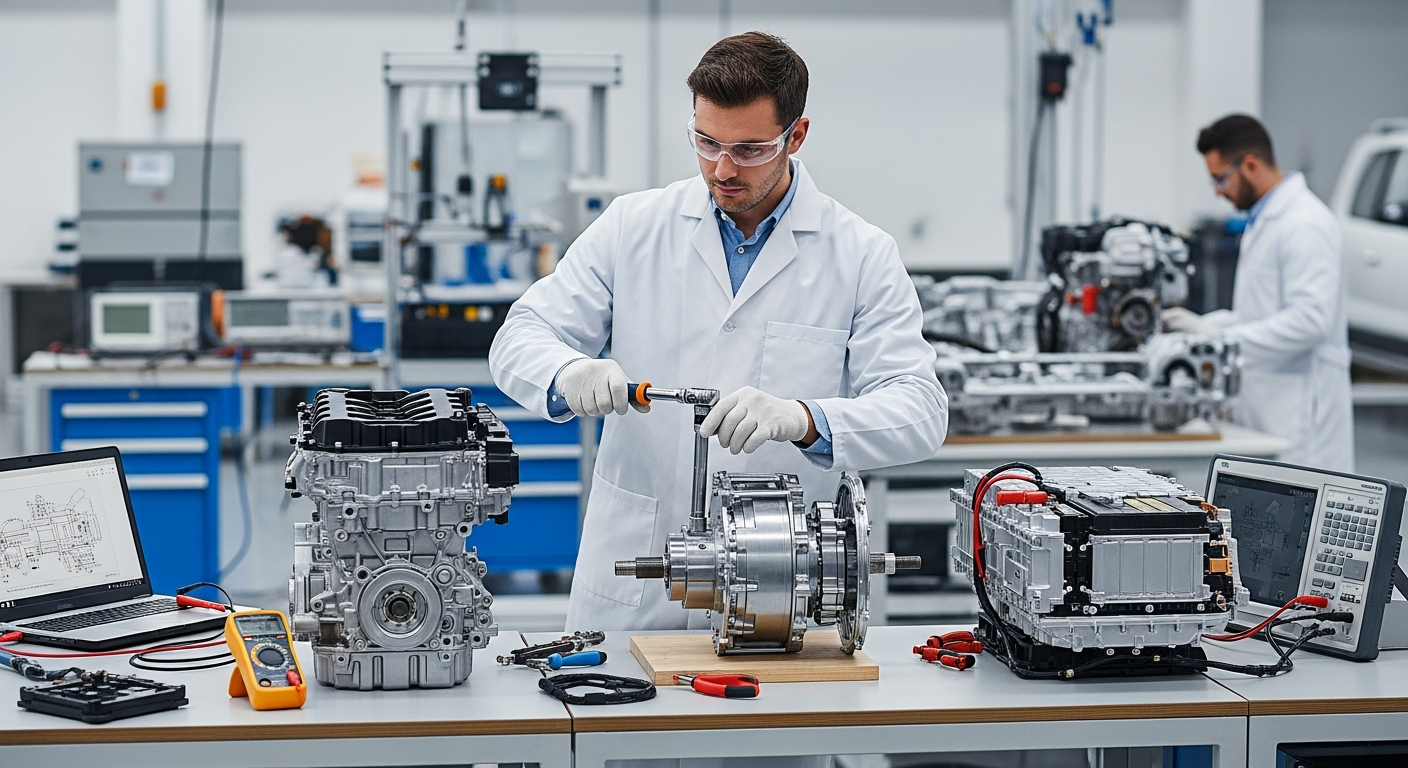

Hybrid powertrain technology integrates an internal combustion engine (ICE) with one or more electric motors, often powered by a battery pack. This combination allows vehicles to operate using either power source independently or in conjunction, optimizing energy use based on driving conditions. The primary goal of this innovative technology is to improve fuel economy and lower exhaust emissions compared to conventional gasoline or diesel vehicles, contributing to more sustainable mobility on the road.

Understanding Hybrid Powertrain Fundamentals

The fundamental concept behind hybrid powertrains involves leveraging the strengths of both electric motors and internal combustion engines. Electric motors are highly efficient at lower speeds and provide instant torque, making them ideal for city driving and starting from a stop. Internal combustion engines, conversely, are generally more efficient at higher speeds and for sustained power output. By intelligently switching between or blending these power sources, hybrid vehicles can achieve better overall performance and efficiency across a wider range of travel scenarios.

Types of Hybrid Powertrain Systems

Hybrid systems are broadly categorized into several types, each with a distinct approach to integrating electric and engine power. Mild hybrids use a small electric motor to assist the engine, providing torque assist and enabling features like engine stop-start. Full hybrids can operate solely on electric power for short distances and at low speeds. Plug-in hybrids (PHEVs) feature larger batteries that can be charged externally, offering a more substantial electric-only driving range before the internal combustion engine engages. Range-extended electric vehicles (REEVs) use the engine primarily as a generator for the electric motor, which directly drives the wheels.

Advantages and Operational Aspects

The advantages of hybrid powertrains extend beyond just fuel efficiency. Many hybrid vehicles exhibit smoother acceleration due to the electric motor’s immediate torque delivery. Regenerative braking, a common feature, converts kinetic energy typically lost during deceleration into electricity to recharge the battery, further boosting efficiency. This intelligent energy management system contributes to a quieter driving experience, especially at lower speeds when the vehicle operates in electric-only mode. The continuous innovation in these systems also enhances the overall performance and reliability of the vehicles.

Technological Advancements in Hybrid Design

Recent advancements in hybrid technology have led to more sophisticated control systems and improved battery design. Lighter materials and advanced aerodynamics are also being incorporated into vehicle design to further reduce energy consumption. The integration of advanced driver-assistance systems (ADAS) and connectivity features often complements hybrid powertrains, enhancing overall safety and user experience. Furthermore, continuous research in battery chemistry and electric motor manufacturing promises even greater efficiencies and reduced costs in the future.

Maintenance and Longevity Considerations

While hybrid vehicles share many maintenance requirements with conventional cars, they also have specific considerations. The electric components, such as the battery pack and electric motors, are generally designed for the vehicle’s lifespan and often come with substantial warranties. Regular checks of the braking system, which experiences less wear due to regenerative braking, and proper tires maintenance are still crucial for safety and efficiency. Understanding the specific suspension and powertrain requirements for your hybrid model can help ensure its longevity and optimal performance.

| Hybrid Type | Key Components | Operational Principle | Primary Benefit |

|---|---|---|---|

| Mild Hybrid (MHEV) | Small electric motor/generator, 12V/48V battery | Assists ICE, enables engine stop/start, torque assist | Improved fuel efficiency, lower emissions |

| Full Hybrid (HEV) | Electric motor, ICE, larger battery pack | Can operate on electric, ICE, or both simultaneously | Significant fuel efficiency gains |

| Plug-in Hybrid (PHEV) | Electric motor, ICE, large rechargeable battery | Extended electric-only range, external charging | Zero-emission driving for daily commutes |

| Series Hybrid | Electric motor drives wheels, ICE acts as generator | ICE charges battery, electric motor powers vehicle | Consistent electric power delivery |

| Parallel Hybrid | Both electric motor and ICE can drive wheels independently or together | Direct power transfer from both sources to wheels | Flexible power delivery, strong acceleration |

Hybrid powertrain technology continues to evolve, offering a compelling blend of efficiency, performance, and reduced environmental impact. From the initial concepts of combining an internal combustion engine with an electric motor to the sophisticated plug-in systems of today, these vehicles represent a significant step towards more sustainable mobility. As advancements in battery technology and vehicle design persist, the role of hybrid vehicles in the broader transportation landscape is expected to grow, providing diverse options for driving on the road globally.